I. Material Structure and Protective Mechanism

The rust-proof aluminized Woven Membrane employs a precisely designed five-layer composite structure, with each layer providing a specific protective function. The substrate layer uses high-strength polypropylene woven fabric, a specially treated substrate with excellent mechanical properties. The warp and weft density of the woven fabric is precisely calculated, typically between 60-80 threads per 10 cm. This structural design ensures both tensile strength and good flexibility. The substrate surface undergoes corona treatment, achieving a surface tension of over 42 dynes/cm, creating ideal conditions for the firm adhesion of subsequent functional layers.

The functional layers consist of two key components: an aluminized barrier layer and a rust-proof functional layer. The aluminized layer is formed through a high-vacuum evaporation process, with the aluminum layer thickness strictly controlled within the range of 500-700 angstroms. This extremely thin metal layer constitutes a continuous and dense barrier, effectively preventing the penetration of oxygen, water vapor, and other corrosive media. The rust-proof functional layer utilizes vapor phase rust prevention technology, uniformly distributing a special rust inhibitor onto the material surface through a microencapsulation process. These microcapsules slowly release rust-preventive components within the packaging environment, creating a protective atmosphere.

The protective mechanism is based on a triple-protection principle. First, the aluminized layer provides a physical barrier that effectively isolates external corrosive media; second, the vapor-phase rust inhibitor forms a protective atmosphere within the confined space, inhibiting electrochemical corrosion reactions on the metal surface; and third, the contact-type rust inhibitor forms a monomolecular protective film on the metal surface, preventing direct contact between corrosive agents and the metal surface. This multi-layered protection mechanism, through synergistic action, provides reliable rust protection for metal products.

The material's environmental adaptability has been rigorously tested and verified. In an accelerated testing environment of 45°C and 95% relative humidity, metal samples inside the packaging showed no signs of rust within 500 hours. Salt spray testing results showed that under continuous spraying with a 5% sodium chloride solution, the time for the first rust to appear on the samples exceeded 400 hours. Long-term storage tests indicate that metal products packaged in this way can remain rust-free for 24 months under normal storage conditions.

II. Production Process and Technical Characteristics

The production of the rust-preventive Aluminized woven film is a precision manufacturing process integrating multiple modern technologies. Production begins with the preparation of the substrate, using high-isotactic polypropylene as the raw material. The polypropylene is melted and plasticized using a twin-screw extruder under precise temperature control of 185-215℃. The melt passes through a five-layer precision filtration system to remove impurities and is then formed into a tubular film through a ring die. This tubular film is biaxially stretched under a specific temperature gradient to form a substrate film with uniform molecular orientation. The process parameters in this step directly affect the mechanical properties and dimensional stability of the substrate.

The weaving process utilizes a computer-controlled intelligent shuttleless loom. The equipment is equipped with an automatic warp tension control system and a real-time monitoring device to ensure the stability and consistency of the weaving process. The warp and weft densities are precisely adjusted according to rust-proof requirements, and a reinforced weaving process is used in stress concentration areas to significantly improve the material's durability. During weaving, a high-speed camera system monitors the fabric quality in real time; any defects trigger automatic alarms and adjustment mechanisms.

Vacuum metallization is the core technology in the production process. In a high-vacuum environment above 10⁻³ Pa, 99.99% high-purity aluminum wire evaporates at a precisely controlled temperature, and aluminum atoms are uniformly deposited on the substrate surface in gaseous form. This process is monitored in real-time by an online laser film thickness monitor, ensuring the uniformity of the aluminum plating layer thickness is controlled within ±3% of the error range. The aluminum-plated material immediately enters a temperature- and humidity-controlled curing chamber for stabilization treatment. This process significantly enhances the bonding strength between the aluminum layer and the substrate, extending the product's lifespan.

Rust prevention utilizes an innovative microencapsulation technology. A special composite rust inhibitor and a polymer carrier material are mixed using a high-pressure micro-jet device to create a submicron-level emulsion, which is then spray-dried to form microcapsules with slow-release properties. These microcapsules are uniformly applied to the material surface using a precision slit coating device, with the coating amount precisely controlled within the range of 18-28 g/m² according to the rust prevention grade requirements. The coated material undergoes a three-stage gradient drying process, with the temperature gradually increasing from 55℃ to 80℃ to ensure strong adhesion and maintain the activity of the rust inhibitor.

Post-processing steps include surface finishing, quality inspection, and finished product packaging. Each roll of product undergoes a comprehensive scan by an online automatic inspection system; any quality defects are automatically marked and sorted. Qualified products are packaged in dust-proof and moisture-proof containers and stored in a constant temperature and humidity warehouse at 23±2℃ and 50%±5% relative humidity. A comprehensive quality traceability system is established throughout the entire production process, achieving full traceability from raw materials to finished products.

III. Performance Characteristics and Quality Requirements

The performance characteristics of the rust-proof aluminized woven film are reflected in several aspects. Rust prevention is its core advantage, verified through multiple international standard tests. Damp heat tests show that in a harsh environment of 55℃ and 95% relative humidity, the metal samples inside the packaging remain intact for 480 hours. Cyclic corrosion tests demonstrate that the material still provides reliable protection under various corrosive environments, including simulated industrial atmospheres and marine climates. Electrochemical tests prove that its rust-proof effect can shift the corrosion potential of metals positively, significantly improving the metal's corrosion resistance.

Mechanical properties are also good. The longitudinal tensile strength of the material can reach over 45MPa, and the transverse tensile strength is not less than 38MPa. Tear strength test results show that its value can reach over 150N/mm. Bursting strength tests show that the material can withstand forces exceeding 300N without breaking. These excellent mechanical properties ensure the material remains intact during loading, unloading, and transportation, providing continuous and reliable protection for the contents. The elongation of the material is controlled within a reasonable range, ensuring ease of use while preventing excessive deformation that could affect the protective effect.

Barrier properties have undergone rigorous testing. Water vapor transmission rate is controlled below 0.5 g/m²·24h, and oxygen transmission rate does not exceed 0.2 cm³/m²·24h. This barrier performance provides crucial assurance for rust prevention. The material also exhibits good oil and chemical resistance, resisting the erosion of most industrial chemicals. UV blocking rate tests show that the material achieves a UV blocking effect of over 99%, effectively preventing the impact of photoaging on the contents.

Environmental adaptability reaches industry-leading levels. UV aging tests show that after 1500 hours of continuous UV irradiation, the material retains over 85% of its main performance indicators. High and low temperature alternating tests show that the material maintains stable performance within an extreme temperature range of -50℃ to 100℃. Weather resistance tests prove that the material retains good rust prevention properties after 12 months of outdoor exposure. These characteristics enable the material to adapt to various storage and transportation environments from frigid to tropical zones.

Quality requirements are strict and clearly defined. Raw materials must comply with RoHS environmental standards, and each batch of raw materials undergoes comprehensive testing for more than twenty performance indicators. More than fifty quality control points are established in the production process, and process parameters for each step are recorded in real time and retained for more than three years. Finished product inspection adopts AQL sampling standards to ensure the statistical stability of product quality. All products are accompanied by detailed quality certification documents, and a comprehensive quality traceability system is established to ensure that any quality problems can be traced back to the specific production stage.

IV. Application Areas and Practical Value

In the equipment manufacturing industry, rust-proof aluminized woven film demonstrates significant value. Large machine tools, precision instruments, and other equipment have extremely high requirements for rust prevention. Using this material for packaging can effectively protect products from corrosion during storage and transportation. A heavy machinery manufacturing company reported that after adopting rust-proof aluminum-coated woven membrane, the return rate of equipment exported to high-temperature and high-humidity areas decreased by 85% within one year, significantly improving the international competitiveness of the products.

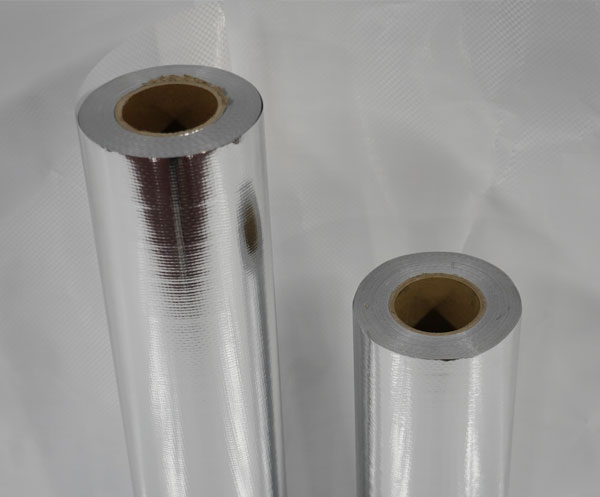

Rust-Proof Aluminized Woven Membrane: Multi-Scenario Industrial Transportation and Warehousing solutions (Data-Comparison Version)

Rust-proof Aluminized woven membrane is a high-performance industrial protective material, made from PET/PE woven fabric laminated with an aluminum layer and VCI rust inhibitor. Compared with ordinary rust-proof films and rust-proof paper, it provides superior corrosion resistance, moisture barrier, and mechanical protection for equipment transportation and warehousing.

Rust Protection Duration:

Rust-proof aluminized woven membrane: up to 24 months in typical indoor storage.

Ordinary rust-proof films: 6–12 months.

Rust-proof paper: 3–6 months.

The combination of aluminized layer and VCI inhibitor forms a dense protective film on metal surfaces, significantly extending rust-free duration.

Moisture and Gas Barrier:

Aluminized woven membrane: Water vapor transmission rate (WVTR) 0.2–1.5 g/(m²·24h), blocks oxygen and corrosive gases.

Ordinary rust-proof films: WVTR 5–10 g/(m²·24h), limited oxygen barrier.

Rust-proof paper: WVTR 10–15 g/(m²·24h), minimal protection against moisture and air.

The aluminized layer reflects over 95% of UV and thermal radiation, reducing environmental degradation of equipment surfaces.

Mechanical Protection:

Aluminized woven membrane: High tear resistance, puncture resistance, and compression resistance; suitable for heavy machinery and sharp-edged equipment.

Ordinary films: Moderate tensile strength; prone to puncture under heavy loads.

Rust-proof paper: Low tear and puncture resistance; limited for transport stacking.

Long-Distance Transport: Forms sealed bags or covers for sea, air, and multimodal shipping, isolating salt spray, humidity, and dust, reducing damage to heavy machinery and precision instruments.

Warehousing Protection: Serves as dust-proof and moisture-proof liners or pallet covers; suitable for indoor and outdoor storage, maintaining stable environmental conditions.

Special Scenarios: Container liners and crate inner packaging; combined with cushioning materials for sharp-edged devices to maintain seal integrity.

The membrane is lightweight, recyclable, and customizable in thickness (0.08–0.2 mm), basis weight (70–180 g/㎡), and optional features such as anti-static or flame-retardant coatings. Correct selection and proper sealing ensure long-term rust protection, reducing maintenance and replacement costs compared to conventional solutions.

Frequently Asked Questions (FAQs):

1. How long does the rust protection effect of the aluminized Woven Membrane last?

The Aluminized woven membrane combines aluminum layer barrier and VCI vapor phase corrosion inhibitor technology, providing up to 24 months of rust protection under typical indoor storage conditions. Compared to ordinary rust-proof films (6–12 months) and rust-proof paper (3–6 months), its rust protection period is significantly extended, making it suitable for long-term storage and export transportation needs.

2. How does this material protect equipment during transportation and warehousing?

The membrane material blocks moisture, oxygen, and corrosive gases through the aluminum layer, while reflecting ultraviolet rays and heat radiation, preventing surface aging of the equipment. The woven fabric substrate provides high tear resistance, puncture resistance, and compression resistance, able to withstand handling, stacking, and sharp-edge impacts, ensuring the integrity of the equipment's appearance and structure.

3. Can the membrane specifications be customized according to equipment requirements?

Yes. Rust-resistant aluminized woven membrane supports customized thickness (0.08–0.2 mm), basis weight (70–180 g/㎡), width, and size, and can also be customized with flame-retardant, anti-static, or UV-resistant functions. Customers can choose the most suitable specifications based on equipment size, weight, and transportation or storage environment to achieve protection in multiple scenarios.

4. What are the advantages compared to ordinary rust-resistant film and rust-resistant paper?

Rust-resistant aluminized woven membrane has a longer rust-resistant cycle, stronger barrier performance, and higher mechanical strength. It not only blocks moisture and oxygen but also reflects heat radiation, preventing equipment aging. It is also tear-resistant and puncture-resistant, making it suitable for packaging heavy equipment and precision instruments, significantly reducing transportation and storage risks.

5. What are the precautions for use and environmental treatment?

When using, select the appropriate thickness and basis weight according to the equipment size to ensure complete coverage and a proper seal. Sharp edges should be cushioned with cushioning material to prevent damage to the membrane. After disposal, the products can be sorted and recycled, and some products support degradation treatment, meeting environmental protection standards and reducing the environmental impact of packaging waste.

This website uses cookies to ensure you get the best experience on our website.