Aluminum foil is a hot stamping material made by directly rolling metallic aluminum into thin sheets. Due to aluminum's softness, good ductility, and silvery-white luster, the rolled sheets can be laminated onto offset paper with substances like sodium silicate to create aluminum foil sheets, which can then be printed on. However, aluminum foil itself is prone to oxidation and darkening, and rubbing or touching will cause discoloration, making it unsuitable for hot stamping on book covers and other long-term preservation applications.

Due to its excellent properties, aluminum foil is widely used in food, beverages, cigarettes, pharmaceuticals, photographic negatives, and household goods, typically as packaging material; it is also used as a material for electrolytic capacitors; as insulation material in buildings, vehicles, ships, and houses; and as decorative gold and silver threads, wallpaper, and decorative labels for various stationery and light industrial products. Among these applications, packaging material is where aluminum foil's performance characteristics are most effectively utilized. Aluminum foil is a flexible metal film that not only possesses advantages such as moisture resistance, airtightness, light blocking, abrasion resistance, aroma retention, and non-toxicity and odorlessness, but also enjoys greater popularity due to its elegant silvery-white luster and ease of processing into various beautiful patterns and designs. In particular, when aluminum foil is laminated with plastic and paper, the shielding properties of aluminum foil are combined with the strength of paper and the heat-sealing properties of plastic, further enhancing its essential shielding performance against moisture, air, ultraviolet rays, and bacteria, significantly expanding its application market. Because the packaged items are completely isolated from external light, moisture, and air, the packaging is perfectly protected. Especially for packaging steamed or boiled foods, using this composite aluminum foil material can guarantee that the food will not spoil for at least a year. Furthermore, it is convenient to heat and open, making it very popular with consumers.

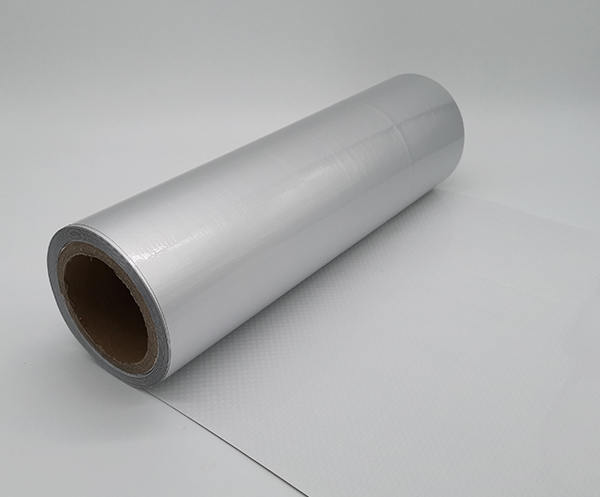

Multi-Scenario White Card Composite Aluminum Foil Film: Preferred Choice for Transportation and Warehousing

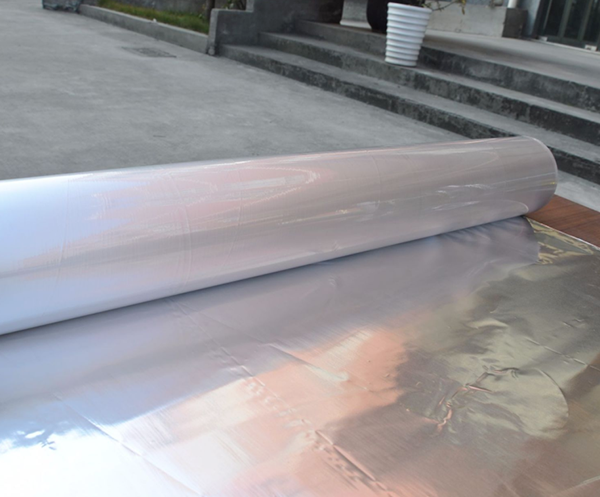

White card composite aluminum foil film is a high-performance protective material made by dry lamination of white card paper and aluminum foil. It combines the rigidity of white card with the barrier properties of aluminum foil, offering protection, printability, and versatile adaptability. It is an ideal material for multi-scenario industrial transportation and warehousing, with no company endorsements included.

Comprehensive Barrier Protection: The aluminum foil layer fully blocks moisture, oxygen, corrosive gases, and ultraviolet light, preventing corrosion of metal components, oxidation of precision parts, and surface aging. The white card substrate provides excellent rigidity, resists compression, and prevents deformation, ensuring the integrity of equipment structure and appearance.

Flexible Operation and Adaptability: Supports heat-sealing and customized dimensions, suitable for manufacturing sealed bags, liners, and covering films. It adapts to heavy machinery, electronic instruments, chemical materials, and other items of various specifications. The white card surface can be printed with labels for easy warehouse identification, and optional anti-static or flame-retardant coatings can meet specialized requirements.

Weather Resistance and Eco-Friendliness: Can withstand temperatures from -30°C to 110°C, suitable for combined sea-land transportation and outdoor storage. Some products are recyclable, aligning with green industrial trends.

Transportation: Can isolate salt spray, dust, and rain during sea and land transport, protecting sensitive industrial equipment.

Warehousing: Can be used as moisture-proof liners or pallet covers, suitable for both indoor and outdoor storage. Lightweight properties do not add transport costs, and the rigidity of the white card reduces packaging deformation risk.

When in use, sharp edges should be paired with cushioning materials to ensure sealing and protection effectiveness.

Frequently Asked Questions (FAQs):

1. How long does the White cardboard composite aluminum foil film provide moisture and corrosion protection?

The aluminum foil layer completely blocks moisture, oxygen, and corrosive gases. Combined with the mechanical support of the white cardboard, it is suitable for long-term storage. Under normal storage conditions, it can effectively prevent moisture and corrosion for more than 12 months. The protective effect can be further extended when used with sealed bags or vacuum packaging, making it suitable for export transportation and long-term storage.

2. What transportation and storage scenarios is it suitable for?

This material is suitable for various industrial transportation and storage scenarios, including sea transport, land transport, container lining, pallet covering, and open-air storage. It can isolate salt spray, rainwater, dust, and ultraviolet rays, while the white cardboard provides resistance to compression and deformation, ensuring the safety of equipment in complex environments.

3. Can sizes and functions be customized?

Film specifications can be customized according to the customer's equipment dimensions, and heat sealing splicing is supported. Antistatic and flame-retardant coatings can be added as needed, or labels can be printed on the white cardboard surface for easy warehouse management and equipment classification. A wide range of customization options are available to meet the protection requirements of various industrial equipment.

4. What are the advantages compared to ordinary packaging materials?

Compared to simple white cardboard or ordinary plastic film, composite aluminum foil film possesses high barrier properties, pressure resistance, and weather resistance. The aluminum foil blocks moisture and oxygen, while the white cardboard provides structural support. The lightweight design does not increase transportation costs, and some products are recyclable, balancing environmental protection and economy.

5. What precautions should be taken during use?

When using, select the appropriate thickness according to the equipment size. For sharp edges, it is recommended to use cushioning material to prevent punctures to the film layer and affect the protective effect. For vacuum or sealed packaging, the seal should be checked regularly to ensure long-term stability of moisture-proof and corrosion-proof effects.

This website uses cookies to ensure you get the best experience on our website.