I. Basic Concepts and Structural Design of Aluminized woven film

Aluminized woven film is a functional packaging material created by combining a "plastic woven base fabric" with an "aluminized film" through a composite process. Its core advantage lies in the fusion of "strength" and "function"—possessing both the tensile and puncture resistance of woven film and the barrier, light-blocking, and reflective properties of the aluminized layer.

(I) Basic Definition and Core Characteristics

"Aluminized woven film" is not a specific material name, but a general term for "high-quality plastic base material," emphasizing the stability and performance consistency of the base material. "Aluminized" refers to the aluminum layer (typically 30-50 nanometers thick) formed on the film surface through a vacuum aluminizing process, giving the material barrier properties. "Woven film" refers to the base fabric made from polypropylene (PP) or polyethylene (PE) as raw material, which is extruded, stretched into flat filaments, and then woven together to provide basic strength.

The core features of this material include:

Composite structure: Composed of at least two layers—a woven base fabric and an aluminized layer. Some products may include an outer protective film or an inner heat-sealing layer, forming a multi-layered composite structure.

Functional synergy: The woven base fabric provides mechanical support (tensile strength, tear resistance), while the aluminized layer provides functional properties (oxygen and moisture barrier, light shielding). Together, they meet complex packaging requirements.

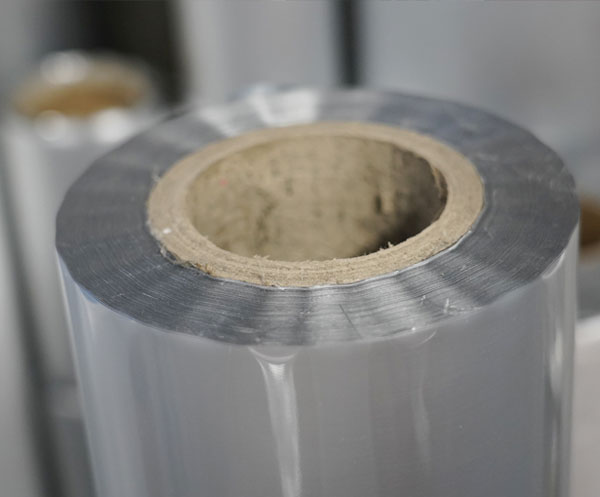

Flexible form: Can be manufactured into rolls (for automatic packaging machines) or bags (such as ton bags, center-seam bags) according to needs, with thicknesses ranging from 0.15 mm (lightweight packaging) to 0.5 mm (heavyweight packaging).

(II) Structural Composition and Functions of Each Layer

The performance of aluminized woven film is determined by the materials of each layer. A typical three-layer composite structure (from outside to inside) and its functions are as follows:

1. Outer Layer: Protective and Abrasion-Resistant Layer

Usually, polypropylene (PP) or polyethylene (PE) film is used, with a thickness of 0.03-0.05 mm. Its main functions are:

Protecting the aluminized layer: Preventing the aluminized layer from peeling off due to friction and collision during transportation and processing (the aluminized layer is brittle and easily damaged when directly exposed);

Improving abrasion resistance: The smooth surface of PP/PE Film resists repeated friction (such as mutual friction during stacking), extending the material's service life;

Printing compatibility: Some outer layer films undergo corona treatment (increasing surface tension), allowing direct printing of patterns and text (such as product information and brand logos), resulting in clear printing effects that are not easily faded.

2. Middle Layer: Core Functional Layer

This is the key structural difference from ordinary Woven Membranes, composed of a "woven base fabric" and a "metallized film":

Woven Base Fabric: Woven from PP flat yarns (0.2-0.3 mm in diameter), the weave density (e.g., 12×12 yarns/cm) determines the base strength—higher density results in better tensile strength.

Metallized Film: Typically aluminized PET (polyester) or aluminized CPP (cast polypropylene) film, 0.012-0.02 mm thick. The aluminum layer is deposited onto the film surface using a vacuum evaporation process, forming a dense barrier layer.

Both layers are bonded together with an adhesive (e.g., polyurethane adhesive). It is crucial to ensure composite strength (peel strength ≥ 0.8 N/15 mm) to prevent delamination and functional failure.

3. Inner Layer: Heat-Sealing and Adaptive Layer

Select PE or CPP film (thickness 0.04-0.06 mm) according to usage requirements. Its main functions are:

Providing heat-sealing properties: PE/CPP has a low melting point (120-160℃), allowing for heat-sealing to achieve a tight seal (e.g., when making bags, a tight seal prevents leakage);

Adapting to contents: The inner layer material must be compatible with the packaged contents (e.g., food-grade PE for food packaging, corrosion-resistant CPP for chemical packaging);

Cushioning protection: A softer inner layer reduces the risk of punctures to the middle aluminized layer by the contents (e.g., when packaging granular items, preventing sharp edges from abrading the aluminized layer).

Aluminized woven film Analysis: Durable and Efficient packaging solutions

Aluminized woven film is a composite packaging material made from polypropylene (PP) or polyethylene (PE) woven fabric as the substrate. Through a vacuum aluminization process, an ultra-thin aluminum layer is applied to the surface and firmly bonded using specialized adhesives, forming a “woven substrate + aluminized barrier layer” core structure. This unique material combination retains the high-strength characteristics of traditional woven films while adding multiple functionalities through the aluminum layer, making it a durable and efficient high-quality packaging solution.

Durability is one of the core advantages of aluminized woven film. The woven fabric substrate is made of high-strength flat yarns interlaced to provide excellent tensile strength, resisting compression, puncture, and abrasion during storage and transport. The aluminized layer further enhances weather resistance, reflecting over 80% of visible light, effectively blocking UV rays, slowing material aging, and extending the service life of packaging. In addition, the metallic aluminum layer provides good electrical conductivity, dissipating static electricity and reducing accumulation, which lowers safety risks in chemical, electronic, and other sensitive applications. This makes it suitable for long-term use in complex and harsh environments.

High-efficiency protection and adaptability highlight its packaging value. The aluminized layer offers excellent barrier performance, with oxygen transmission rates below 1.0 cm³/m²·24h·atm and water vapor transmission rates below 1.0 g/m²·24h, effectively isolating moisture, oxygen, corrosive gases, and odors. This prevents the contents from dampness, oxidation, or contamination, making it ideal for grains, chemical raw materials, precision components, and other products with high protection requirements. Additionally, its lightweight design reduces logistics weight costs, and customizable processing allows adjustment of thickness and dimensions to meet different packaging needs. Combined with printing, it can enhance package recognition, balancing protection with brand display requirements. Aluminized woven film is widely used across industrial, logistics, food, pharmaceutical, and other sectors.

Frequently Asked Questions (FAQs):

1. What are the core materials and structural advantages of Aluminized woven film?

Aluminized woven film uses polypropylene (PP) or polyethylene (PE) woven fabric as the base material, and laminates it with an extremely thin aluminum film layer through a vacuum aluminizing process, forming a "woven base material + aluminized barrier layer" structure. This structure combines high strength, wear resistance, puncture resistance, and excellent barrier performance, making it suitable for complex industrial and logistics packaging environments.

2. How does aluminized woven film ensure the safety of goods during transportation?

The high-strength woven base material provides compression and tear resistance, while the aluminum film layer blocks moisture, oxygen, and corrosive gases, preventing materials from becoming damp, oxidized, or contaminated. The metallic properties also release static electricity, reducing safety hazards for chemical or electronic materials during transportation and storage, ensuring long-term stable and reliable packaging.

3. Which industries and packaging scenarios are suitable for aluminized woven film?

Aluminized woven film is widely used in the industrial, logistics, food, pharmaceutical, chemical, and electronics industries. It can be used in various scenarios such as heavy material protection, precision component transportation, chemical raw material storage, and food and pharmaceutical packaging, meeting high protection requirements and safety needs in long-term storage and transportation environments.

4. What are the customization services included for aluminized woven film?

We can customize film thickness, width, composite layer type, and functional additives (such as UV resistance, moisture resistance, corrosion resistance, and antistatic properties) according to customer needs. We can also combine it with printing processes to enhance packaging recognizability, achieving the dual functions of protection and brand display, meeting the packaging requirements of different products.

5. What are the advantages of aluminized woven film in logistics and transportation?

Its lightweight design reduces logistics weight costs, and the high-barrier layer prevents moisture, oxygen, and odor intrusion, protecting the integrity of goods. Its high tensile strength and self-adhesive properties can tightly secure palletized goods, reducing shaking or collision damage during handling and long-distance transportation, improving packaging efficiency, and adapting to the diverse transportation needs of the global supply chain.

This website uses cookies to ensure you get the best experience on our website.