Applications of Aluminum foil rolls

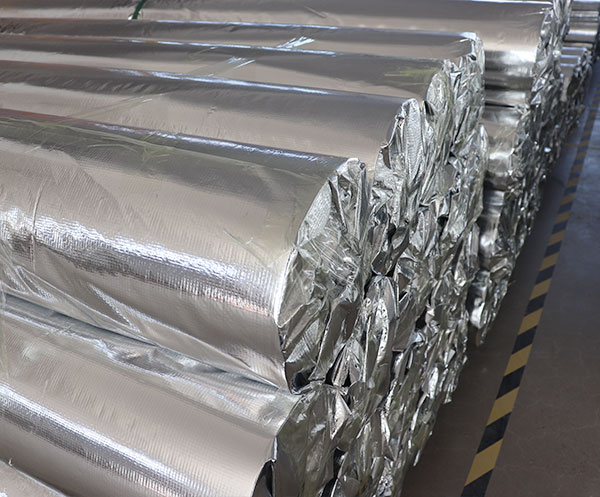

Aluminum foil rolls are high-performance roll products made from high-purity aluminum foil as the core material, formed through continuous rolling, composite processing, and winding. Their unique material properties and processing technology make aluminum foil rolls widely applicable in various fields such as industry, logistics, food, pharmaceuticals, electronics, and construction. Aluminum foil itself possesses characteristics such as lightweight, high strength, corrosion resistance, strong barrier properties, resistance to high and low temperatures, and good plasticity. Through roll form, customized sizes, thicknesses, and composite properties can be achieved according to different application requirements, improving packaging efficiency and ease of use.

In the industrial packaging field, aluminum foil rolls are widely used for protective packaging of heavy materials, chemical raw materials, and sensitive equipment. Aluminum foil has excellent puncture and tear resistance, effectively resisting compression, collisions, and mechanical damage during transportation and storage. At the same time, the composite layers enhance barrier properties, preventing the intrusion of dust, moisture, and chemical media into the materials, thereby ensuring the integrity and safety of the goods. For example, using aluminum foil rolls for packaging chemical raw materials, building materials, or high-precision mechanical parts during long-distance transportation can significantly reduce the risk of damage and improve logistics efficiency.

In the logistics and transportation sector, aluminum foil rolls are lightweight, durable, and available in customizable widths and thicknesses for various packaging methods such as container dust covers, pallet wrapping, and cargo bundling. Aluminum-coated composite rolls also offer moisture-proof, rust-proof, and UV-resistant properties, providing highly reliable protection for precision goods such as electronic instruments and optical equipment. Their high tensile strength and self-adhesive properties allow for tight securing of goods, reducing displacement and damage during transportation, while simplifying the packaging process and reducing labor costs. Their temperature resistance allows the rolls to adapt to complex logistics environments such as high and low temperatures, alternating periods of heat and humidity, and outdoor storage, ensuring consistent quality from warehousing to the end customer.

In the food and pharmaceutical packaging sector, the high barrier properties, moisture resistance, and non-toxicity of aluminum foil rolls provide reliable protection for product freshness and extended shelf life. Aluminum foil can be laminated with food-grade PE, PET, or other composite materials to create packaging bags, vacuum packaging films, or multi-layer composite rolls for packaging dry food, beverages, pharmaceuticals, and health products. Its UV protection effectively delays the deterioration of photosensitive products, ensuring consumers receive high-quality and safe goods.

Electronic product packaging is a significant application area for aluminum foil rolls. High-precision electronic components are extremely sensitive to humidity, oxidation, and static electricity. Aluminum foil rolls can be laminated with moisture-proof paper, foam, or anti-static materials to form a sealed protective space, blocking moisture, dust, and corrosive media, ensuring the performance stability of electronic components during warehousing, transportation, and long-term storage. Aluminum-plated composite rolls can also provide electromagnetic shielding, meeting the packaging needs of specialized electronic products.

In the construction and industrial covering sector, aluminum foil rolls can be used as waterproof, moisture-proof, heat-insulating, or thermal insulation materials. For example, in roofing, wall, or pipe cladding, aluminum foil rolls can extend the lifespan of building structures through heat reflection, moisture blocking, and corrosion resistance. Meanwhile, its flexibility and ease of processing enhance construction efficiency and adaptability to diverse installation needs.

In summary, aluminum foil rolls, with their advantages of high strength, lightweight, strong protection, resistance to high and low temperatures, and customizability, have become a core material for packaging and protection across multiple industries. From heavy industrial packaging to logistics and transportation protection, from food and pharmaceutical preservation to electronic product security, and even building covering and thermal insulation, aluminum foil rolls play an irreplaceable role in modern industry and daily life due to their superior performance and wide adaptability. By choosing high-quality aluminum foil rolls, companies can not only improve packaging efficiency and ensure cargo safety but also reduce packaging costs, meeting the requirements of green environmental protection and sustainable development.

High-strength aluminum foil Rolls Enhance Safety in Industrial and Logistics Transportation

High-strength Aluminum foil rolls, made from aluminum alloy as the core material and processed through specialized rolling and composite techniques, combine high tensile strength, excellent barrier properties, and impact resistance. In industrial and logistics transportation scenarios, they serve as a key packaging material to protect cargo quality and ensure transport safety. Their unique material advantages precisely address multiple risks in complex transportation environments, providing comprehensive protection for a wide range of goods.

In industrial packaging, high-strength aluminum foil rolls meet the protection needs of diverse materials, including building materials, chemical raw materials, and precision components. For heavy industrial products such as steel and aluminum, their high rigidity and tear resistance effectively prevent crushing and puncture during handling, avoiding damage to edges and corners. For chemical raw materials and other environmentally sensitive items, the sealed barrier structure of aluminum foil isolates moisture, oxygen, and corrosive gases, preventing oxidation, deterioration, or leakage, thereby reducing transportation safety risks. In the new energy sector, aluminum foil rolls can be customized for specialized packaging, providing anti-static and contamination protection for sensitive materials such as lithium battery electrodes, ensuring the safe transport of production materials.

Throughout the logistics supply chain, the adaptability and protective performance of high-strength aluminum foil rolls are even more pronounced. In long-distance transport, including maritime shipping and railway transfer, their excellent waterproof and moisture-proof properties resist condensation caused by high humidity and temperature fluctuations, preventing cargo from moisture damage. When combined with corner protectors, plastic steel straps, and other accessories, they form a stable packaging structure that reduces movement and impact damage during transport. Additionally, the lightweight nature of aluminum foil rolls lowers transport weight costs without compromising protection, and their recyclability supports the development of green logistics.

From protecting heavy industrial goods to preserving precision materials, from short-distance transport to international shipping, high-strength aluminum foil rolls, through customized specifications and functional adaptations, establish a comprehensive transportation safety protection system, providing essential support for efficient and secure industrial production and logistics operations.

Frequently Asked Questions (FAQs):

1. In which industrial and logistics transportation scenarios is High-strength aluminum foil roll suitable?

High-strength aluminum foil roll is suitable for the packaging and transportation of heavy industrial materials, chemical raw materials, precision equipment, and electronic components. In logistics, it can be used for container dust covers, pallet wrapping, cargo bundling, and long-distance cross-regional transportation, ensuring the safety and stability of goods during handling, loading, unloading, and transportation.

2. What are the advantages of the core materials of aluminum foil roll?

Aluminum foil roll uses aluminum alloy as its core base material, combined with special rolling and composite processes, possessing advantages such as high tensile strength, tear resistance, impact resistance, strong barrier properties, and waterproof and moisture-proof properties. These characteristics enable it to effectively resist mechanical damage, moisture, and corrosive media in complex transportation environments.

3. How does high-strength aluminum foil roll ensure the safety of transporting precision or sensitive materials?

Aluminum foil rolls can be used in conjunction with antistatic paper, foam, or composite materials to form a sealed protective space, blocking moisture, dust, and oxidizing gases. Simultaneously, the aluminized composite layer provides a certain degree of corrosion resistance and electromagnetic shielding, effectively ensuring the stability of sensitive materials such as electronic components and lithium battery electrodes during transportation and storage.

4. How does aluminum foil roll perform in long-distance transportation and various environmental conditions?

Aluminum foil rolls are lightweight and highly adaptable, able to withstand high humidity, drastic temperature changes, and outdoor environments. Combined with corner protectors, plastic straps, and other auxiliary components, a stable packaging structure can be formed, reducing the risk of goods shaking and collision. At the same time, the self-adhesiveness and high tensile strength of the roll improve packaging efficiency and reduce labor costs.

5. Can aluminum foil rolls be customized for different goods?

Yes. Roll materials can be customized according to thickness, width, composite layers, and functional additives (such as UV resistance, moisture resistance, corrosion resistance, and antistatic properties) to meet diverse needs such as heavy industrial materials, low-temperature transportation, outdoor storage, and precision logistics, providing customers with tailor-made safe transportation solutions.

This website uses cookies to ensure you get the best experience on our website.