In the context of the rapid development of today's packaging industry, metallized woven film manufacturers, as a crucial link in the industrial chain, bear important responsibilities in product research and development, manufacturing, and quality control. These companies provide the market with high-performance, stable-quality metallized woven film products through continuous technological innovation and process improvement. From raw material procurement to production processes, from quality management to customer service, every link reflects the professionalism and responsibility of the manufacturing enterprise.

I. Production Equipment and Technological Strength

The core competitiveness of metallized woven film manufacturers is primarily reflected in their production equipment and technological strength. Modern production enterprises are typically equipped with complete production lines from raw material processing to finished product packaging. In the raw material processing stage, automated batching systems and precision extrusion equipment are used to ensure the accuracy of raw material proportions and the uniformity of melt plasticization. The screw design of the extruder is specially optimized to ensure the uniformity of the plastic melt while maintaining high output.

The weaving process uses computer-controlled intelligent weaving equipment. This equipment is equipped with automatic warp breakage detection systems and real-time tension control systems, ensuring the stability of the weaving process and the consistency of the product. Advanced looms can reach speeds of over 200 revolutions per minute while maintaining low noise and energy consumption. Some manufacturers have also introduced digital monitoring systems to collect and analyze various parameters during the weaving process in real time, achieving intelligent management of the production process.

Vacuum metallization equipment is the core component of the production line. Modern metallization equipment employs multi-chamber continuous coating technology, with more than 10 vacuum chambers, enabling continuous production. The equipment is equipped with an automatic yarn feeding system, a precision evaporation source, and an online film thickness monitor to ensure the uniformity and consistency of the metallized layer. The vacuum level during the metallization process can be maintained at 10⁻³ Pa, and the evaporation temperature control accuracy reaches ±5 degrees Celsius. These precise controls provide reliable assurance for product quality.

Post-processing equipment also reflects the manufacturer's technical strength. The coating machine uses a precision metering pump and an automatic correction system, controlling the coating thickness deviation within ±2%. The printing equipment is equipped with a digital color management system, enabling accurate color reproduction and clear pattern printing. The investment in these advanced equipment not only improves production efficiency but also ensures the stability of product quality.

II. Quality Management System

Establishing a sound quality management system is the foundation for metallized woven film manufacturers. Strict quality control is implemented from the moment raw materials enter the warehouse. Each batch of raw materials undergoes testing for multiple indicators, including melt flow index, density, and ash content, to ensure compliance with production requirements. Suppliers are required to provide complete quality certification documents, and regular on-site audits are conducted to ensure the stability of raw material quality.

The quality control points in the production process are scientifically and rationally set. In the flat yarn production process, an online monitoring system monitors the thickness and width of the flat yarn in real time, automatically triggering an alarm if deviations exceed the set range. The weaving process is equipped with a fabric density meter to ensure that warp and weft densities meet standards. In the aluminizing process, an online spectrometer monitors the thickness of the aluminized layer, allowing for timely detection and adjustment of process parameters. Detailed operating procedures and inspection standards have been established for each process.

Finished product inspection employs multiple testing methods. In addition to routine visual inspection and dimensional measurement, performance testing is also conducted. The mechanical properties laboratory is equipped with an electronic tensile testing machine to test the tensile strength, elongation at break, and other indicators of the materials. Barrier performance testing uses water vapor transmission rate and oxygen transmission rate testers to verify the product's protective performance. An aging test chamber simulates different environmental conditions to evaluate the product's durability.

A comprehensive and rigorous quality traceability system is in place. Through an information management system, all data for each batch of products, from raw materials to finished products, is recorded. This data includes raw material batch numbers, process parameters, and inspection results, enabling full traceability. When quality issues arise, the problematic环节 can be quickly located, and corrective measures can be taken. A regular quality analysis meeting system ensures that quality issues are resolved promptly and the quality system is continuously improved.

III. R&D and Innovation Capabilities

The sustainable development of Aluminized woven film manufacturers is inseparable from R&D and innovation. The R&D team typically consists of professionals from multiple disciplines, including materials science, mechanical engineering, and chemical engineering. The R&D center is equipped with advanced experimental equipment, including small extruders, experimental coating equipment, and material testing instruments, enabling the development and verification of new products and processes.

In new materials R&D, the manufacturer continuously explores new raw materials and formulations. By adding nanomaterials to improve the mechanical and barrier properties of products, developing biodegradable and environmentally friendly materials to reduce environmental impact, and developing special functional masterbatches to give products special functions such as antistatic and UV resistance, these innovations not only improve product performance but also expand the application areas of the products.

Process improvement is another key focus of R&D work. By optimizing extrusion process parameters, the quality stability of flat yarns is improved; the weaving process is refined to enhance fabric uniformity; and the aluminum plating process is innovated to improve aluminum layer adhesion and uniformity. These process improvements enhance product quality while also increasing production efficiency and resource utilization.

Product development focuses on market demand. For the food packaging sector, a product series compliant with food safety standards is developed; for the industrial packaging sector, high-strength, heavy-duty models are developed; and for special application scenarios, products with anti-mildew and insect-proof functions are developed. Through close collaboration with customers, the R&D team accurately grasps market demands and develops more competitive products.

IV. Environmental Protection and Sustainable Development

Modern aluminized woven film manufacturers highly value environmental protection and sustainable development. Clean production processes are actively promoted. Energy and material consumption are reduced by optimizing equipment structure and process parameters; volatile organic compound (VOC) emissions are reduced by installing waste gas treatment devices; and a wastewater recycling system is established to improve water resource utilization. These measures not only reduce environmental impact but also lower production costs.

Raw material selection prioritizes environmental friendliness. Raw materials that meet environmental standards are given priority, and the use of harmful substances is avoided. Developing recyclable and biodegradable new materials to promote the greening of packaging materials. Collaborating with suppliers to establish a green supply chain system to ensure the environmental performance of products from the source.

Strict waste management regulations. Scrap materials and waste generated during production are collected separately. Recyclable components are processed and reused, while non-recyclable components are outsourced to professional organizations for disposal. A waste management ledger is established to record the generation, treatment, and disposal of waste, ensuring compliance with environmental requirements.

Increasingly refined energy management. Smart meters are installed to monitor energy consumption in real time at each process stage. Data analysis identifies and optimizes high-energy-consuming processes. High-efficiency motors and energy-saving equipment are adopted to improve energy utilization efficiency. Some manufacturers have also begun using renewable energy sources such as solar power to further reduce carbon emissions.

Aluminized woven film for Moisture-Proof and Protective Packaging of Industrial Equipment

Aluminized woven film is a key material for moisture-proof and protective packaging of industrial equipment. It is composed of PET/PE woven fabric laminated with a vacuum-deposited aluminum layer, offering high barrier performance, strong mechanical properties, and adaptability. It provides comprehensive protection for industrial equipment throughout the logistics and storage process. The following sections describe its performance, applications, and usage considerations, without mentioning any company.

Superior Moisture Barrier

The aluminized layer achieves a water vapor transmission rate (WVTR) as low as 0.2–1.5 g/(m²·24h), effectively blocking water vapor, oxygen, and corrosive gases. It prevents equipment from moisture-induced corrosion and oxidation of components. Additionally, the aluminum layer reflects ultraviolet radiation and heat, reducing aging of painted or plastic parts and minimizing temperature fluctuation impacts on precision equipment.

High Mechanical Strength

The woven fabric substrate provides excellent tear resistance, puncture resistance, and compression strength. It can withstand edge abrasion, stacking pressure, and friction during transport and storage, protecting the equipment’s appearance and structural integrity.

Flexible Functions and Specifications

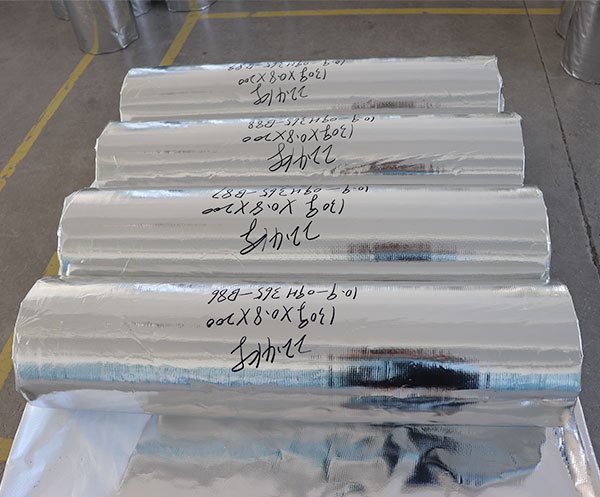

The material supports heat sealing and can be customized in size, thickness (0.08–0.2 mm), and basis weight (70–180 g/m²). Functional coatings such as antistatic or flame-retardant layers can be added to adapt to different equipment requirements. Some variants are recyclable, aligning with environmental standards.

Transport Protection

In sea freight and multimodal logistics, the film can be made into sealed packaging bags or protective covers, isolating equipment from salt spray, moisture, and humid air. It reduces damage risk for heavy machinery, machine tools, and electronic instruments. For precision equipment, vacuum packaging can further limit oxygen and moisture exposure, protecting internal components. Its lightweight design reduces transportation and packaging costs.

Storage Protection

Used as dust covers, moisture-proof liners, or pallet overlays, the film creates a stable storage environment. It slows aging for long-term stored equipment and reduces maintenance costs. In outdoor storage, it protects against rain, snow, and sun exposure, preventing environment-induced equipment failures and extending service life.

Special Scenario Adaptation

The film can form sealed protective layers in container linings, wooden crate interiors, or other specialized packaging scenarios, preventing moisture intrusion. This is especially suitable for long-term export equipment protection.

Select appropriate thickness and basis weight according to equipment size and weight to ensure full coverage and proper sealing. Use cushioning materials around sharp edges to prevent film puncture. For vacuum packaging, check seal integrity and periodically inspect stored packages to ensure consistent long-term moisture-proof performance.

Frequently Asked Questions (FAQs):

1. What are the main protective functions of aluminized Woven Membrane?

Aluminized woven membrane is a composite of a vacuum-deposited aluminized layer and PET/PE woven fabric, achieving highly efficient moisture protection, oxidation prevention, and barrier against corrosive gases. Simultaneously, the aluminum layer reflects ultraviolet rays and heat radiation, reducing the impact of temperature differences on precision equipment. The woven substrate gives it high tear resistance, puncture resistance, and compression resistance, ensuring the integrity of equipment during transportation and storage.

2. What transportation and storage scenarios is this product suitable for?

Aluminized woven membrane is particularly suitable for sea freight, multimodal transport, and long-term storage. It can be made into sealed packaging bags, covers, or box liners to isolate moisture, salt spray, and dust, providing comprehensive protection for heavy machinery, machine tools, electronic instruments, and other equipment. Precision equipment can be used in conjunction with vacuum packaging to further isolate oxygen and moisture, ensuring the safety of internal components.

3. Can material specifications be customized?

Yes. We offer customized solutions in varying thicknesses (0.08–0.2mm), basis weights (70–180g/㎡), and widths based on the size, weight, and protection level requirements of our clients' equipment. We also offer optional antistatic and flame-retardant coatings to meet the packaging needs of different industrial environments and export equipment.

4. What are the advantages compared to ordinary plastic film or Aluminum Foil Bags?

Metallized woven film combines high barrier properties with excellent mechanical strength. Compared to ordinary plastic film, its moisture barrier, oxidation resistance, and puncture resistance are significantly improved; compared to ordinary aluminum foil bags, the woven substrate increases tear resistance and abrasion resistance, making it more suitable for packaging sharp-edged or heavy equipment. Furthermore, the lightweight material helps reduce transportation costs.

5. What precautions should be taken during use?

Choose an appropriate thickness and basis weight to cover the entire surface of the equipment and ensure proper sealing at the edges. Sharp edges of the equipment should be reinforced with cushioning material to prevent the film from being punctured. When vacuum packaging, the integrity of the seal must be checked, and warehouse packaging should be sampled regularly to ensure long-term moisture protection and stable protective effects.

This website uses cookies to ensure you get the best experience on our website.