There are many methods for aluminum foil lamination in aluminum foil woven fabrics. Based on the basic process, aluminum foil lamination can be broadly categorized into several methods. Suzhou Yisheng has been conducting various experiments on solvent-free aluminum foil lamination since its inception, striving to gain successful experience. Based on our years of research and experimentation, aluminum foil composite materials can be mass-produced, but the reliability for large-scale application still needs improvement. Many users find aluminum foil lamination difficult to master, and the main reasons for the problems are as follows: aluminum foil is a rigid substrate with a very small thickness, while the initial tack of the adhesive is relatively low, making it difficult to form a good initial bond.

Aluminum foil lamination is usually a three- or four-layer structure. We recommend two methods to users: the step-by-step method and the one-step method.

1. Step-by-Step Method: The step-by-step method involves laminating two layers at a time. Three-layer structures are completed in two steps, and four-layer structures in three steps. Between two laminations, either full curing or partial curing can be used. We strongly recommend the partial curing method, i.e., laminating again within 2-4 hours after the previous lamination. The partial curing method is an original invention of Tongze, which can reduce back-seepage defects, shorten the production cycle, and improve efficiency.

2. One-Step Method The one-step method refers to completing the lamination of three or four layers in a single operation. Of course, this requires appropriate equipment. Different processes lead to different problems. Based on our years of experience working with users, we offer solutions to several common issues.

These two aluminum foil lamination methods are still widely used and suitable for aluminum foil woven fabrics.

Aluminum foil composite woven film: High-Performance Industrial Transportation and Storage Material

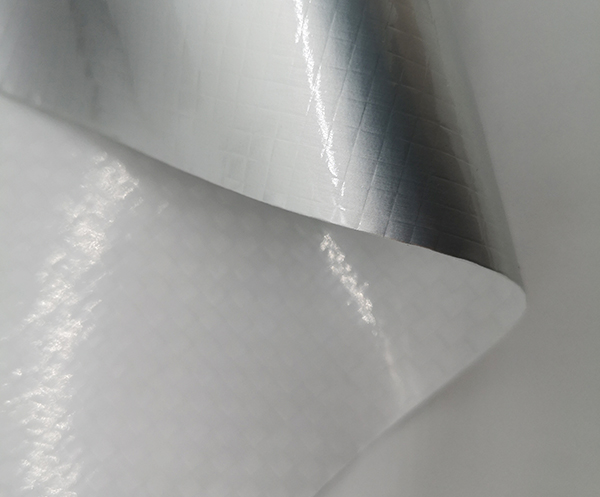

Aluminum foil composite woven film is a high-performance industrial protective material made by hot-laminating aluminum foil onto PET/PE woven fabric. Combining excellent barrier properties, mechanical strength, and weather resistance, it provides ideal protection for industrial equipment during transportation and storage. The following description contains no company promotion.

Its core advantages are threefold:

Superior Barrier Protection: The aluminum foil layer fully blocks moisture, oxygen, and corrosive gases, preventing equipment corrosion and component oxidation. It also reflects ultraviolet light and thermal radiation, protecting equipment surfaces from aging and preventing precision components from temperature-induced damage.

Excellent Mechanical Performance: The woven fabric substrate gives the material high tear resistance, puncture resistance, and compression strength. It withstands edge scratches, stacking pressure, and friction during transport and storage, maintaining the integrity of equipment appearance and structure.

Flexible Adaptability: Supports heat sealing, splicing, and size customization. Optional anti-static or flame-retardant coatings can be added, meeting the packaging needs of heavy machinery, electronics, and other industrial equipment of varying specifications.

In application scenarios, the membrane can be formed into sealed transport bags or protective covers, isolating salt spray in sea transport and dust during land transport. For storage, it serves as a dust-proof and moisture-proof liner or pallet cover, providing a stable environment for long-term equipment storage. Its lightweight property does not add extra transport costs, and some products are recyclable, aligning with green industrial development trends.

Usage Tips: Select appropriate thickness based on equipment weight and edge characteristics. Use cushioning for sharp edges to ensure a complete seal and maintain protective performance.

Frequently Asked Questions (FAQs):

1. How effective is the Aluminum foil composite woven film in terms of moisture and corrosion protection?

The aluminum foil composite woven film effectively prevents equipment from rusting and components from oxidation by blocking moisture, oxygen, and corrosive gases through the aluminum foil layer. Its ability to reflect ultraviolet rays and heat radiation avoids surface aging and temperature-induced damage, making it suitable for long-term transportation and storage environments.

2. How much mechanical stress can this material withstand during transportation?

The woven fabric substrate gives the film high tear resistance, puncture resistance, and compression resistance, enabling it to withstand scratches from equipment edges, stacking pressure, and handling friction, effectively protecting the structural and aesthetic integrity of heavy machinery, precision instruments, and electronic equipment.

3. Can aluminum foil composite woven film be customized?

Yes. The material supports heat-sealing and custom sizes, with thickness (0.08–0.2mm) and basis weight (70–180g/㎡) adjustable according to equipment specifications. Antistatic or flame-retardant coatings can be added to meet the packaging and protection needs of various industrial equipment.

4. What are the advantages compared to ordinary packaging films or moisture-proof paper?

Aluminum foil composite woven film is superior to ordinary plastic films and moisture-proof paper in terms of moisture protection, corrosion protection, UV protection, and mechanical protection. It has a longer protection period, stronger tear resistance, and forms a sealed protective layer, reducing equipment damage and maintenance costs during transportation and storage.

5. What are the precautions for use and recycling?

When using, select the appropriate thickness based on the weight and edge characteristics of the equipment, and add cushioning material to sharp areas to ensure a complete seal. After disposal, it should be sorted and recycled. Some products can be recycled and reprocessed, meeting environmental standards and helping to reduce the environmental impact of industrial packaging waste.

This website uses cookies to ensure you get the best experience on our website.