In recent years, woven fabric aluminum foil has become increasingly popular, not only in industrial manufacturing but also in people's daily lives. So, what are the specific applications of woven fabric aluminum foil? Let's take a look.

I. Shockproof Packaging:

1. Packaging for televisions, refrigerators, home appliances and electrical products, electronic instruments and office supplies.

2. Static electricity protection packaging for precision instruments, ceramics, glass, and optical instruments.

3. Damage-proof packaging for building materials, furniture, lacquerware, and musical instruments.

II. Packaging for Various Export Products and Daily Necessities:

1. Lining materials for various bags and suitcases, thermal insulation bags.

2. Materials for various travel mats, automotive heat-insulating and sun-shielding films.

III. Materials for Agriculture, Aquaculture, and Sports:

1. Thermal insulation and protection materials for greenhouses, buoyancy materials for various aquaculture industries.

2. Buoyancy materials for life jackets and life rings.

Multifunctional 150g aluminum foil composite woven fabric: industrial equipment protection Material

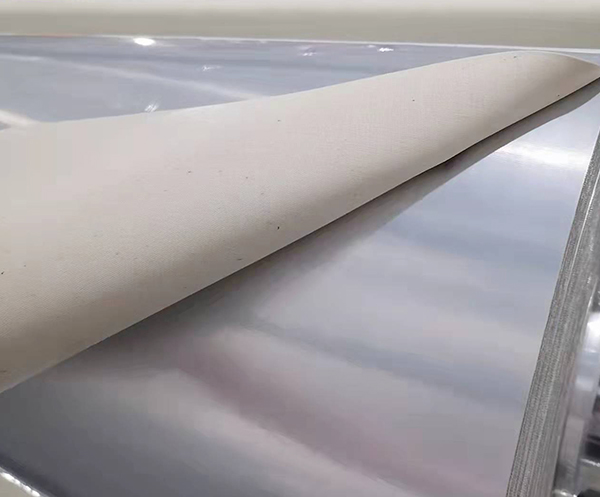

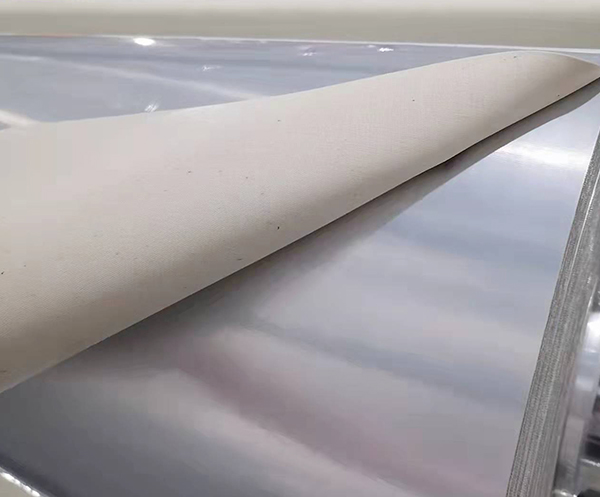

The 150g Aluminum foil composite woven fabric is a lightweight, high-performance industrial protective material. With a standard basis weight of 150g/m², it balances protection and practicality. Made by hot-melt laminating aluminum foil with polyester (PET) woven fabric, it features moisture resistance, tear resistance, and weather durability, making it an ideal choice for industrial equipment transportation and storage protection. No company recommendations are included.

Core Performance Advantages:

Superior Barrier Protection: The aluminum foil layer completely blocks water vapor, oxygen, and corrosive gases, preventing metal components from rusting and precision parts from oxidizing. It also reflects ultraviolet light and heat radiation, preventing surface aging of equipment and embrittlement of plastic components.

High Strength and Damage Resistance: The 150g woven fabric substrate provides excellent tear and puncture resistance. It protects against scratches, stacking pressure, and friction during transportation and storage, maintaining the appearance and structural integrity of equipment.

Flexible and Easy to Use: Supports heat sealing, splicing, and customized sizing. Can be made into protective covers, packaging bags, or container liners. Optional anti-static or flame-retardant coatings enhance suitability for heavy machinery, electronic instruments, and various industrial equipment.

Practical Applications:

In transportation, it isolates equipment from sea salt spray and road dust. In storage, it serves as a dust- and moisture-proof covering suitable for both indoor and outdoor conditions. Its lightweight nature does not increase transportation costs, and some products are recyclable, aligning with green industrial practices. For equipment with sharp edges, cushioning materials are recommended to avoid puncturing the aluminum foil layer and ensure sealed protection.

Frequently Asked Questions (FAQs)

1. How is the moisture-proof performance of this 150g Aluminum foil composite woven fabric?

The aluminum foil layer completely blocks water vapor, oxygen, and corrosive gases, with a water vapor permeability as low as 0.2-1.5g/(m²·24h), effectively preventing corrosion of metal parts and oxidation of electronic components. Simultaneously, its aluminum film reflects ultraviolet rays and heat radiation, reducing the risk of aging caused by long-term storage or transportation.

2. Is the material wear-resistant and damage-resistant during transportation?

The 150g woven fabric base gives the material high tear resistance, puncture resistance, and compression resistance, resisting scratches from sharp edges, stacking pressure, and frictional impacts during transportation, effectively protecting the appearance and internal structure of industrial equipment.

3. Can the size or additional functions be customized?

The size, thickness, and weight can be customized according to equipment specifications. Heat-sealing, antistatic, or flame-retardant coatings can also be added. It can be made into covers, packaging bags, or container liners to meet the protection needs of various industrial transportation and storage scenarios.

4. What storage environments is the material suitable for?

It is suitable for both indoor and outdoor storage environments. Indoors, it can be used as a dustproof and moisture-proof lining or pallet cover; in outdoor storage, it can withstand rain, snow, sunlight, and temperature differences, ensuring stable protection for long-term stored equipment.

5. What precautions should be taken when using it?

Select specifications suitable for the size and weight of the equipment. Sharp edges should be cushioned to avoid puncturing the aluminum foil layer. After vacuum packaging or sealing, the seal should be checked regularly to ensure long-term effectiveness in preventing moisture, rust, and damage.

This website uses cookies to ensure you get the best experience on our website.