Vacuum metallized films used in packaging have the following characteristics:

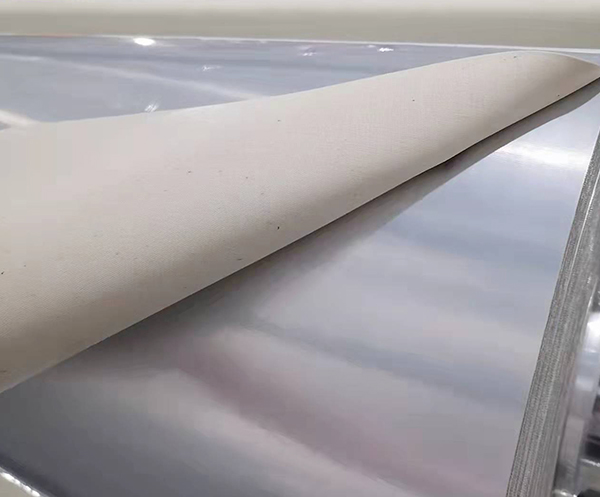

Vacuum evaporation metallization is a process that uses resistance, high frequency, or electron beam heating to melt and vaporize metal under high vacuum (above 10⁻⁴ mbar), depositing it onto the surface of a film substrate to form a composite film. The metal material to be deposited can be gold, silver, copper, zinc, chromium, aluminum, etc., with aluminum being the most commonly used. A very thin layer of metallic aluminum is deposited on the surface of plastic film or paper to create metallized film or metallized paper.

(1) Compared to aluminum foil composites, it significantly reduces the amount of aluminum used, saving energy and materials, and lowering costs. The thickness of aluminum foil used in composites is mostly 7-9 μm, while the aluminum layer thickness of metallized film is approximately 400 μm (0.04 μm), consuming about 1/200th the aluminum of aluminum foil. Production speed can reach up to 700 m/min.

(2) It has excellent folding resistance and good toughness, rarely exhibiting pinholes and cracks, without bending or cracking, and improved barrier properties against gases, water vapor, odors, and light. (3) It possesses excellent metallic luster, with a light reflectivity reaching 97%; and can be coated to form colored films, offering a decorative effect unmatched by aluminum foil.

(4) Partial aluminizing can be achieved through shielding or washing to obtain arbitrary patterns or transparent windows, allowing visibility of the packaged contents.

(5) The aluminized layer has good electrical conductivity, eliminating static electricity, especially when packaging powdered products, preventing contamination of the sealing area and ensuring the packaging's airtightness.

(6) It exhibits good adaptability to post-processing such as printing and lamination.

Due to these characteristics, aluminized film has become a high-performance, economical, and aesthetically pleasing new type of composite film, replacing aluminum foil composite materials in many applications. It is mainly used for packaging export goods, industrial chemicals, and precision electronic equipment and instruments.

High-strength three-in-one aluminum foil film: Core Material for Moisture and Rust Protection of Precision Instruments

High-strength three-in-one aluminum foil film is a high-performance protective material composed of a PET outer layer, an aluminum foil barrier layer, and a PE heat-sealable inner layer through thermal lamination. With features of high barrier performance, mechanical strength, and strong adaptability, it is the core choice for moisture and rust protection during the transportation and storage of precision instruments. This description contains no company recommendations.

Superior Moisture and Rust Protection: The aluminum foil layer fully blocks water vapor (WVTR ≤ 0.3 g/(m²·24h)) and oxygen (OTR ≤ 0.5 cm³/m²·24h). Combined with the PE inner layer seal, it prevents metal components from rusting and electronic parts from oxidizing. The aluminum layer reflects over 95% of UV light, preventing the aging of instrument surfaces and plastic parts, suitable for long-term storage requirements.

High Strength and Damage Resistance: The PET outer layer and composite structure provide excellent tear resistance and puncture strength, with tensile strength up to 200 N/15mm and puncture resistance ≥ 30 N. This ensures protection against scratches, stacking pressure, and impact during transport and storage, maintaining the integrity of precision instruments.

Flexible Adaptability: Supports heat sealing and size customization. Can be made into vacuum packaging bags or sealed covers to fit various instrument sizes. Additional features such as VCI vapor-phase rust inhibitors and anti-static coatings can be added for enhanced rust and electrostatic protection, meeting the requirements of electronic and precision instruments.

During transportation, the film can be made into vacuum-sealed bags to block sea salt, moisture, and humidity, reducing damage rates. In storage, it can serve as dust-proof and moisture-proof liners, providing a stable environment for long-term storage of precision instruments. The material is lightweight and does not significantly increase shipping costs, and some products are recyclable, aligning with green packaging initiatives.

When using, select the appropriate specifications according to instrument size. Use cushioning materials for sharp edges to prevent film damage. After vacuum packaging, check sealing integrity and periodically inspect protection performance to ensure stable moisture and rust prevention.

Frequently Asked Questions (FAQs):

1. How long does this three-in-one aluminum foil film provide moisture and rust protection?

The High-strength three-in-one aluminum foil film combines an aluminum foil barrier layer with a PE heat-sealing inner layer. Under sealed conditions, it blocks moisture and oxygen. Combined with VCI vapor phase rust inhibitors, the moisture and rust protection period for precision instruments can reach 12-24 months. Metal parts and electronic components will remain intact even after long-term storage.

2. What types of precision instruments is it suitable for?

This product is suitable for various precision instruments, including electronic instruments, optical instruments, machine tool parts, precision molds, and high-end measuring equipment. The film material can be customized in size and thickness to fit different instrument specifications and meet transportation and long-term storage needs.

3. Is the film material easily damaged during use?

The film material uses a PET surface layer and composite process, possessing high tear and puncture resistance. If sharp edges may scratch the film material during transportation or storage, it can be reinforced with cushioning materials to ensure sealing and protection.

4. What precautions should be taken during transportation or storage?

When using, select a film material that fits the instrument size and ensure complete coverage of edges and corners. After vacuum packaging, check the seal. Avoid puncturing with sharp objects during transportation or handling. During storage, periodically check the packaging condition to ensure stable moisture-proof and rust-proof performance.

5. Does this material meet environmental and recyclable standards?

The high-strength three-in-one aluminum foil film substrate is recyclable. Some products can have a biodegradable layer added, complying with RoHS, REACH, and other environmental standards. After use, it can be sorted and recycled or disposed of according to standards to reduce the environmental impact of packaging waste.

This website uses cookies to ensure you get the best experience on our website.