Woven Bags are an essential component in modern packaging and material handling. They provide strength, durability, and protection for a wide range of products, from agricultural goods to industrial materials. Among woven bags, two primary types are commonly used: Aluminum‑coated woven bags and regular woven bags. Understanding the differences between these two types is crucial for businesses and industries that require reliable packaging solutions.

This article explores the performance, advantages, disadvantages, and applications of aluminum‑coated woven bags and regular woven bags. It also provides insights into choosing the right type based on material, environmental conditions, and handling requirements. With a focus on quality, durability, and protection, this guide serves as a valuable resource for industrial buyers, warehouse managers, and supply chain professionals.

Regular woven bags are typically made from polypropylene or polyethylene fibers. These fibers are woven into a tight mesh, forming a strong, flexible, and lightweight packaging solution. Regular woven bags are widely used for transporting grains, powders, fertilizers, and other bulk materials.

Cost-effective: Regular woven bags are generally less expensive compared to aluminum-coated alternatives, making them suitable for high-volume applications.

Lightweight: Easy to handle, transport, and store.

Versatility: Suitable for a variety of materials, including agricultural products, construction materials, and food items.

Recyclable: Most regular woven bags can be recycled, promoting sustainability in packaging.

Despite their benefits, regular woven bags have some limitations:

Limited moisture protection: They may allow moisture or dust penetration, risking material contamination.

Lower durability in harsh environments: Regular woven bags are more susceptible to wear and tear under heavy loads or extreme weather conditions.

Shorter lifespan: Frequent handling or storage in adverse conditions can reduce the longevity of regular woven bags.

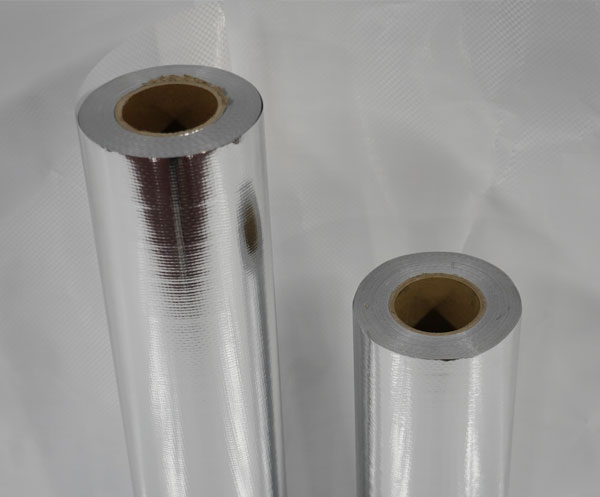

Aluminum‑coated woven bags are constructed from the same woven polypropylene fibers as regular woven bags but feature an additional aluminum coating. This coating significantly enhances the bag’s protective properties, including resistance to moisture, dust, UV rays, and chemical exposure.

Superior protection: Aluminum coating prevents water, dust, and sunlight from damaging the contents.

Increased durability: Coated bags withstand heavy loads, sharp edges, and rough handling.

Longer lifespan: Enhanced protection increases the bag’s usable life, reducing replacement frequency.

Industrial suitability: Ideal for chemicals, fertilizers, powdered materials, and other sensitive products.

Temperature resistance: Aluminum coating provides a barrier against extreme heat or cold during transport and storage.

Higher cost: Aluminum‑coated bags are more expensive due to additional materials and manufacturing processes.

Weight: Slightly heavier than regular woven bags, potentially increasing transportation costs.

Recycling considerations: The aluminum layer may require specialized recycling processes.

| Feature | Aluminum-coated woven bags | Regular Woven Bags |

|---|---|---|

| Moisture Resistance | Excellent | Moderate |

| Dust Protection | High | Medium |

| UV Resistance | High | Low |

| Durability | High | Moderate |

| Load Capacity | Heavy-duty | Standard |

| Lifespan | Extended | Standard |

| Cost | Higher | Lower |

| Ideal Use | Sensitive industrial, agricultural, chemical | General packaging, bulk materials |

| Environmental Impact | Recyclable but needs specialized processing | Easily recyclable |

This comparison clearly demonstrates that aluminum‑coated woven bags outperform regular woven bags in harsh environments and industrial applications where protection and durability are critical.

Regular woven bags are widely used in environments where standard protection and strength are sufficient:

Agriculture: Transporting grains, seeds, and fertilizers.

Construction: Packaging cement, sand, and aggregates.

Food Industry: Storing dry goods such as rice, flour, and sugar.

Warehousing: Bulk storage for non-sensitive materials.

Logistics: General-purpose packaging for shipping and handling.

While regular woven bags are cost-effective, they may not provide adequate protection in high-moisture or high-stress conditions.

Aluminum‑coated woven bags are suitable for industries and conditions where additional protection is essential:

Chemical Industry: Packaging powders, granules, and sensitive chemicals.

Agriculture: Protecting seeds, fertilizers, and agricultural chemicals from moisture.

Food Processing: Maintaining freshness of flour, sugar, or powdered ingredients.

Industrial Manufacturing: Safe transport of raw materials requiring dust and moisture resistance.

Extreme Conditions: Handling in humid, hot, or cold environments.

Aluminum-coated woven bags offer unmatched protection for materials requiring high standards of storage and transport.

When deciding between aluminum‑coated woven bags and regular woven bags, consider the following factors:

For moisture-sensitive or perishable materials, aluminum-coated bags provide superior protection.

For robust, non-sensitive materials, regular woven bags are cost-efficient.

Harsh conditions, such as high humidity, extreme temperatures, or UV exposure, favor aluminum-coated bags.

Standard conditions allow the use of regular woven bags.

Heavy-duty applications benefit from the reinforced structure of aluminum-coated bags.

Standard loads can be managed effectively with regular woven bags.

Evaluate the trade-off between upfront cost and long-term durability.

Aluminum-coated bags may have higher initial costs but reduce replacement frequency and protect sensitive materials.

Proper handling and storage practices enhance the performance of both aluminum‑coated and regular woven bags:

Avoid sharp edges: Prevent punctures or tears.

Store in dry areas: Minimize exposure to moisture and humidity.

Stack correctly: Avoid overloading to prevent deformation or breakage.

Inspect regularly: Check for signs of wear, seam damage, or coating peeling.

Clean appropriately: Remove dust and debris without damaging the bag surface.

Aluminum-coated bags require minimal maintenance due to their protective layer, while regular woven bags may require extra care in humid or dusty environments.

Pros: Lower initial cost, lightweight, recyclable.

Cons: Limited protection, shorter lifespan, potential material contamination.

Pros: Superior protection, durability, long lifespan, suitable for harsh conditions.

Cons: Higher cost, slightly heavier, recycling requires specialized processes.

Investing in aluminum-coated woven bags can reduce operational losses, prevent product damage, and enhance long-term savings despite higher upfront costs.

Increased demand for durable packaging: Industries are prioritizing product protection and operational efficiency.

Sustainable coatings: Research on recyclable and eco-friendly coatings is increasing.

Custom solutions: Businesses seek aluminum-coated bags tailored to specific material types and load requirements.

Global shipping needs: Aluminum-coated woven bags meet international standards for moisture and dust protection during long-distance transport.

Technological advancements: Improved weaving techniques and coating methods enhance the performance of both bag types.

These trends indicate that aluminum-coated woven bags will continue to gain popularity in industries requiring high-performance packaging solutions.

Aluminum-coated woven bags and regular woven bags serve distinct purposes in packaging and material handling. Aluminum-coated woven bags excel in harsh environments, offering superior protection against moisture, dust, UV radiation, and heavy loads. Regular woven bags remain cost-effective and suitable for general packaging needs where high protection is not critical.

When selecting woven bags, consider material sensitivity, environmental conditions, load requirements, and cost. A thorough evaluation ensures that businesses choose the right bag type, protecting materials, reducing operational risk, and optimizing efficiency.

For industries handling bulk materials, chemicals, agricultural products, or sensitive goods, aluminum-coated woven bags provide long-term durability, reliability, and protection. For standard operations and general storage, regular woven bags remain a practical, cost-effective solution. Proper handling, storage, and inspection further enhance performance and ensure optimal packaging outcomes.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)