Woven Bags for heavy duty packaging applications are a critical solution for industries that require robust, reliable, and cost-effective storage and transport of bulk materials. These bags combine the strength of woven polypropylene or polyethylene fabric with specialized construction techniques, allowing them to handle heavy loads, resist tearing, and provide protection against environmental factors. Heavy duty woven bags are widely used in agriculture, construction, chemical industries, logistics, and other commercial sectors.

Heavy duty packaging applications demand materials that can endure stress, rough handling, and exposure to moisture, dust, and other contaminants. Woven bags for heavy duty packaging applications are specifically engineered to meet these requirements, ensuring material integrity, safety, and efficiency during storage and transportation.

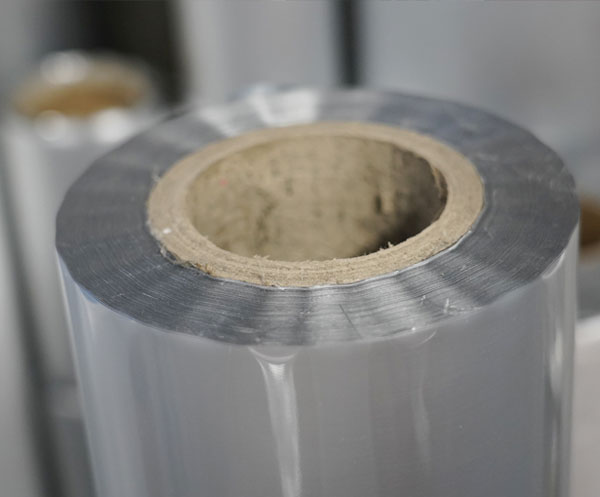

Woven bags for heavy duty packaging applications are primarily made from high-strength polypropylene (PP) or polyethylene (PE) fibers. These fibers are woven into a tight, interlaced structure, providing excellent tensile strength and resistance to tearing. Some bags feature additional lamination or coating to enhance moisture resistance and protect contents from dust and environmental damage.

High Tensile Strength: The woven construction ensures the bags can carry significant weight without tearing.

Durability: Reinforced seams and strong fibers allow these bags to endure repeated handling.

Moisture Resistance: Laminated or coated surfaces prevent water penetration, protecting sensitive materials.

Dust Protection: The tight weave and optional coatings help maintain material purity.

UV Resistance: Some heavy duty woven bags include UV-resistant layers for outdoor storage.

Adaptability: Bags can be manufactured in various sizes, capacities, and styles to meet specific industrial needs.

Open-mouth bags: Simple top opening, easy to fill and seal. Suitable for bulk grains and powders.

Valve bags: Equipped with a filling valve for automated packing of powders or granules.

Gusseted bags: Side folds increase capacity, ideal for large-scale storage.

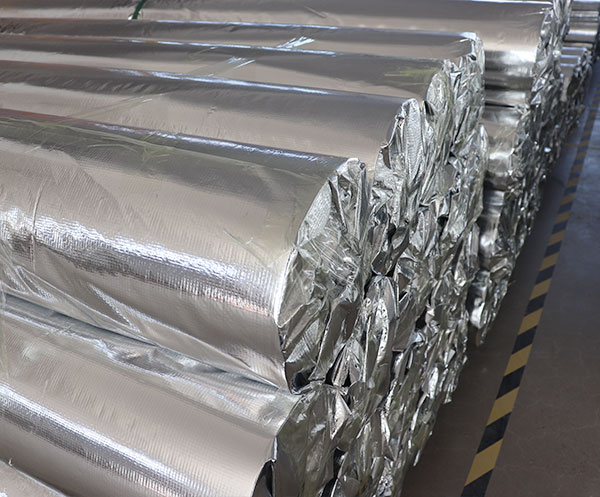

Laminated bags: Aluminum or PE coatings for moisture and dust protection.

Heavy duty woven bags are widely used in agriculture for storing and transporting grains, rice, seeds, fertilizers, and animal feed. These bags prevent spoilage, maintain quality, and facilitate efficient handling during harvest, storage, and transport. Moisture-resistant bags are essential for preserving agricultural products, especially in humid or wet conditions.

In the construction industry, heavy duty woven bags are used for cement, sand, gravel, and other bulk materials. These bags provide durability, resistance to punctures, and protection against environmental factors during handling, storage, and shipping. Large-scale construction projects often rely on woven bags for reliable packaging and material delivery.

Powders, granules, and raw chemical materials require careful handling to prevent contamination or moisture damage. Woven bags for heavy duty packaging applications provide a stable and protective environment for chemicals during storage and transport. Laminated or coated bags offer additional moisture and dust protection for sensitive materials.

Heavy duty woven bags are ideal for logistics and bulk shipping operations. They withstand stacking, long-distance transportation, and exposure to harsh conditions. Efficiently packed woven bags reduce product loss, minimize contamination, and improve operational efficiency for warehouse and transport operations.

Certain woven bags are suitable for storing food products, such as grains, pulses, and dry goods. These bags ensure hygiene, prevent dust infiltration, and maintain product quality during storage and transportation. When used correctly, heavy duty woven bags help meet food safety and handling standards.

Strength and Reliability: Heavy duty woven bags provide exceptional load-bearing capacity, reducing risks of material loss.

Protection Against Moisture and Dust: Coated or laminated bags prevent moisture penetration and protect contents from dust and contamination.

Cost-effectiveness: Durable and reusable, these bags reduce packaging costs over time and minimize material waste.

Ease of Handling: Lightweight but strong, woven bags are easy to stack, transport, and store.

Customizable Options: Bags can be produced in various sizes, colors, and designs to suit different materials and branding requirements.

Sustainability: Many woven bags are recyclable or reusable, making them an Environmentally friendly packaging option.

High-quality woven fabrics provide strength, durability, and resistance to tearing. Polypropylene and polyethylene fibers are preferred for heavy duty packaging applications due to their robustness and chemical resistance.

Aluminum or PE lamination enhances moisture resistance and dust protection. Coatings also improve UV resistance and durability in outdoor storage conditions.

Select bag sizes appropriate for your materials. Proper sizing ensures safe handling, prevents spillage, and optimizes storage and transport efficiency.

Consider the weight and handling conditions of materials. Bags for industrial use must withstand stacking, rough handling, and long-distance transport.

For outdoor storage or shipping, UV-resistant and laminated woven bags ensure long-lasting protection against sunlight, rain, and temperature variations.

Choosing a reliable woven bag supplier ensures consistent quality, timely delivery, and technical support. Experienced suppliers can provide guidance on bag selection, customization, and compliance with industry standards.

Keep Bags Dry: Store in cool, dry areas to prevent moisture damage.

Avoid Sharp Objects: Prevent punctures or tears by keeping bags away from sharp tools and surfaces.

Stacking: Proper stacking reduces crushing and maintains bag integrity.

Inspection: Check for damage before use to avoid contamination or material loss.

Modern woven bags for heavy duty packaging applications are increasingly made from recyclable materials. Reusable bags reduce waste and align with sustainable packaging initiatives. Proper disposal and recycling contribute to environmental responsibility, making woven bags a green packaging solution.

Woven bags for heavy duty packaging applications provide a reliable, cost-effective, and durable solution for multiple industries. Their strength, protective qualities, and adaptability make them suitable for agricultural, industrial, chemical, construction, and food applications. Choosing high-quality woven bags ensures material safety, reduces losses, and enhances operational efficiency.

Investing in heavy duty woven bags provides long-term benefits, including moisture and dust protection, durability, and compliance with handling standards. By selecting bags based on material quality, lamination, size, and environmental resistance, businesses can optimize packaging operations and maintain product integrity in challenging conditions.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)