I. Material Structure and Protective Mechanism

The rust-proof aluminized Woven Membrane employs a precise multi-layered composite structure, with each layer performing a specific protective function. The substrate layer uses high-strength Polypropylene Woven Membrane, a biaxially stretched substrate with excellent mechanical properties. The warp and weft density of the woven membrane is precisely calculated, typically between 48-64 threads per square inch. This structure ensures both tensile strength and appropriate flexibility. The substrate surface undergoes corona treatment, achieving a surface tension of over 40 dynes/cm, providing ideal conditions for the adhesion of subsequent functional layers.

The functional layers consist of an aluminized layer and a rust inhibitor layer. The aluminized layer is formed using a vacuum coating process, with the aluminum layer thickness strictly controlled between 400-600 angstroms. This extremely thin metal layer constitutes a continuous and dense barrier, effectively blocking the penetration of oxygen, water vapor, and corrosive gases. The rust inhibitor layer is the key functional layer of the material. Utilizing vapor phase corrosion inhibition technology, a special rust inhibitor is uniformly distributed on the material surface through a microencapsulation process. These microcapsules slowly release rust-inhibiting components within the packaging environment, creating a protective atmosphere.

The protective mechanism is based on multiple protective principles. First, the aluminized layer provides a physical barrier that effectively isolates external corrosive media. Second, the vapor-phase rust inhibitor forms a protective atmosphere within the packaging space, inhibiting electrochemical corrosion reactions. The contact-type rust inhibitor forms a monomolecular protective film on the metal surface, preventing corrosive agents from contacting the metal surface. This multi-layered protection mechanism ensures comprehensive protection for metal products during storage and transportation.

The material's environmental adaptability has been rigorously verified. In an accelerated testing environment of 40°C and 90% relative humidity, metal samples inside the packaging showed no signs of rust within 480 hours. Salt spray testing results showed that under 5% sodium chloride solution spray conditions, the time for the first rust to appear on the samples exceeded 360 hours. These data demonstrate the material's reliable protective performance in harsh environments.

II. Production Process and Technical Characteristics

The production of the rust-inhibiting Aluminized woven film is a precision manufacturing process integrating multiple modern technologies. Production begins with the preparation of the substrate, using high-isotactic polypropylene as the raw material. The polypropylene is melted and plasticized within a temperature range of 190-220℃ using a twin-screw extruder. After precision filtration, the melt is formed into a tubular film through a ring die and then biaxially stretched at a specific temperature to create a substrate film with uniform orientation.

The weaving process utilizes computer-controlled intelligent weaving equipment. The equipment is equipped with an automatic tension control system and real-time monitoring devices to ensure the stability of the weaving process. The warp and weft densities are precisely adjusted according to rust-proof requirements, with increased density in stress concentration areas to improve material durability. During weaving, an online detection system monitors fabric quality in real time, promptly identifying and addressing any abnormalities.

Vacuum metallization is the core step in the production process. In a high vacuum environment above 10⁻² Pa, high-purity aluminum wire evaporates at 1400-1500℃, and aluminum atoms are uniformly deposited on the substrate surface in gaseous form. This process is monitored in real time by an online film thickness monitor to ensure the uniformity of the metallized layer thickness. The metallized material immediately enters a curing chamber for further treatment to enhance the bonding strength between the aluminum layer and the substrate.

The rust-prevention treatment utilizes advanced microencapsulation technology. A special rust inhibitor and carrier material are mixed using a high-pressure homogenizer to create a nano-emulsion, which is then spray-dried to form microcapsules. These microcapsules are uniformly applied to the material surface using precision coating equipment, with the coating amount controlled within the range of 15-25 g/m² according to the rust prevention grade requirements. The coated material undergoes segmented drying, with the temperature gradually increased from 60℃ to 85℃ to ensure strong adhesion of the rust inhibitor.

Post-processing includes quality inspection and finished product packaging. Each batch of products undergoes comprehensive performance testing, including rust prevention, mechanical properties, and barrier properties. Qualified products are packaged in dustproof packaging and stored in a temperature and humidity controlled warehouse. A complete quality record is maintained throughout the entire production process, ensuring full traceability.

III. Performance Characteristics and Quality Requirements

The performance characteristics of the rust-prevention aluminized woven film are reflected in several aspects. Rust prevention is its core advantage, verified through multiple accelerated tests. Damp heat testing showed that the metal samples inside the packaging remained intact for 480 hours in an environment with a temperature of 55℃ and a relative humidity of 95%. Cyclic corrosion testing demonstrated that the material still provides reliable protection under simulated marine climate conditions. These properties ensure effective protection for metal products even in harsh environments.

Excellent mechanical properties are also observed. The material's longitudinal tensile strength reaches over 35MPa, and its transverse tensile strength is not less than 30MPa. Tear strength testing results show a value exceeding 140N/mm. These mechanical properties ensure the material remains intact during loading, unloading, and transportation, effectively protecting the contents. The material's flexibility allows it to adapt to the packaging requirements of products with different shapes.

Barrier properties have undergone rigorous testing. Water vapor transmission rate can be controlled below 0.8g/m²·24h, and oxygen transmission rate does not exceed 0.3cm³/m²·24h. This excellent barrier performance provides crucial assurance for rust prevention. The material also exhibits good puncture resistance, with a puncture strength test value exceeding 8N, effectively preventing packaging damage during distribution.

High-Strength Rust-Proof Aluminized Woven Membrane: Long-Term Protection for Metal Parts

The High-strength rust-proof aluminized woven membrane, featuring the core advantages of “reinforced structure + multi-layer protection,” is an ideal material for metal parts storage, long-distance transport, and cross-border shipping. It effectively resists moisture, oxidation, friction, and impact, providing long-lasting safety for bolts, nuts, bearings, gears, and other metal components. Its protective features and applications are as follows:

Unique Composite Structure Provides Robust Physical Protection

This material is manufactured using a multi-layer composite process, typically structured as “aluminized layer + PE Film + woven fabric + PE film.” The high-strength woven fabric core offers excellent tear and puncture resistance, easily withstanding sharp edges of metal parts and pressure or friction during transport, preventing membrane damage and ensuring continuous protection. The outer PE film enhances flexibility and wear resistance, maintaining structural stability in complex logistics environments.

Professional Anti-Rust Design for Long-Term Protection

The aluminized layer forms a dense barrier, with water vapor transmission as low as 0.1 g/(m²·24h), effectively blocking moisture, oxygen, and salt spray. It also reflects UV and heat, reducing accelerated corrosion in high-temperature and high-humidity environments. Some premium products integrate VCI vapor-phase corrosion inhibitors, which slowly release molecules that penetrate gaps and concealed areas of parts to form a nanoscale protective film, achieving “contact + vapor-phase” dual anti-rust protection. The rust-prevention effect can last 1–3 years.

Excellent Adaptability and Practicality

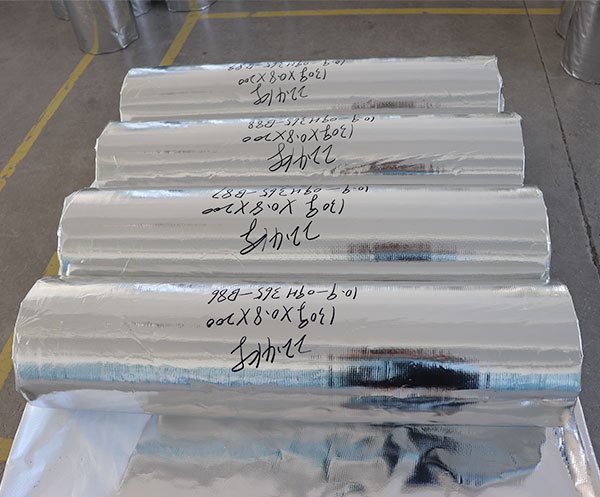

The membrane supports custom specifications with widths from 0.2 m to 2.6 m and thicknesses from 0.08 mm to 0.2 mm. It can be cut for wrapping or processed into packaging bags, accommodating single or bulk packaging needs for metal parts of various sizes. Non-toxic, environmentally friendly, and lightweight, it does not increase shipping costs. Heat sealing and vacuum sealing further enhance protection, making it suitable for full-chain protection of all types of metal components.

Frequently Asked Questions (FAQs):

1. What types of metal parts are suitable for packaging with this high-strength, rust-resistant, Aluminized woven film?

Our aluminized woven film is suitable for various metal parts, including bolts and nuts, bearings, gears, motor components, valves, and large machine tool parts. Whether for single-item packaging or covering entire machines, this product provides long-term, comprehensive protection against rust, moisture, and abrasion.

2. How long does the protection of the rust-resistant, aluminized woven film last?

The standard product, combining an aluminized barrier layer with optional VCI vapor phase corrosion inhibitor technology, provides 1 to 3 years of long-lasting protection. Under dry, sealed conditions, it effectively prevents rust and corrosion of metal parts, even in the high-humidity, salt-spray environment of sea transport.

3. Can the product be customized in size or specifications?

Yes. We support customization of widths from 0.2m to 2.6m and thicknesses from 0.08mm to 0.2mm. We can also cut and process the film into packaging bags or rolls according to customer requirements. Whether it's small precision parts or large equipment, we can provide matching packaging solutions.

4. How much pressure and friction can the product withstand during transportation and storage?

This product uses a high-strength woven fabric composite PE Film, which has strong tear and puncture resistance. It can resist punctures from sharp edges of parts and friction, compression, and collisions during transportation, ensuring the integrity of the film and maintaining the protective effect of metal parts.

5. How environmentally friendly is the product? Is it safe and recyclable?

We use non-toxic and environmentally friendly materials to manufacture aluminized woven film that complies with RoHS environmental standards and is recyclable. The product has no irritating odor, is safe to use, and is suitable for various industrial storage and cross-border transportation, while reducing environmental burden.

This website uses cookies to ensure you get the best experience on our website.