Woven film materials: Definition and Characteristics

Toughness is also a crucial characteristic of woven film materials. Toughness allows the woven film to deform to a certain extent without breaking when subjected to external impact or bending. Polyethylene woven film possesses excellent toughness; it can be bent, folded, and even return to its original shape after a certain degree of twisting. This toughness allows the woven film to effectively buffer external impacts during packaging and transportation, protecting the contents from damage. For example, when transporting fragile items, using polyethylene woven film for packaging can absorb vibration and impact to a certain extent, reducing the risk of breakage.

Chemical resistance is another prominent characteristic of woven film materials. Different woven film materials have varying degrees of resistance to chemical substances, but generally, woven films made of synthetic fibers typically have good chemical resistance. Polypropylene woven film has strong resistance to most acids and alkalis and is widely used in the packaging and storage of chemical products. It can be used to package highly corrosive chemicals such as sulfuric acid and hydrochloric acid, effectively preventing chemical leakage and erosion of the packaging. Polyester woven film exhibits good stability in organic solvent environments, without dissolving or deforming upon contact with organic solvents. Therefore, it plays an important role in industrial production and storage involving organic solvents.

Types of Woven Film Materials

Common Woven Film Materials

Within the vast system of woven film materials, there is a rich variety of common materials, each playing a crucial role in different fields due to its unique performance characteristics.

Polyethylene (PE) is an extremely common woven film material. Its molecular structure is relatively simple, polymerized from ethylene monomers. This structure gives it excellent flexibility. Products made from PE woven film, such as plastic bags and cling film, can be easily bent and folded to adapt to packaging items of various shapes. Its low-temperature resistance is also outstanding. In low-temperature environments, such as cold storage, PE woven film maintains good flexibility and strength, without becoming brittle or cracking due to low temperatures. This makes it widely used in frozen food packaging and low-temperature storage. From a microscopic perspective, the intermolecular forces of PE are relatively weak, which is one reason for its good flexibility. However, this also leads to relatively limited heat resistance. Generally, PE woven film may soften and deform when the temperature exceeds 70℃, so temperature limits must be observed during use.

Polypropylene (PP) woven film is also widely used. It has high strength, stemming from the regular arrangement of its molecular chains and strong intermolecular forces. PP woven film has high tensile strength and is not easily broken under large tensile forces, making it commonly used in the manufacture of industrial packaging bags, freight tarpaulins, and other products that need to withstand significant external forces. PP has good heat resistance, remaining stable at relatively high temperatures, generally withstanding 100℃-120℃. This makes it advantageous in applications requiring high-temperature processing or use in high-temperature environments, such as hot-fill food packaging. However, PP woven film is slightly less flexible than PE, and may not be suitable for applications with extremely high flexibility requirements.

Polyester (PET) woven film performs well in terms of strength and abrasion resistance. PET's molecular structure contains ester groups, which strengthens the intermolecular forces, giving woven films high strength. PET woven films have high tensile and tear strength, capable of withstanding significant impacts and friction. They are commonly used in packaging high-end electronic products, conveyor belts, and other products requiring stringent strength and abrasion resistance. They also exhibit good dimensional stability, with minimal dimensional changes under varying temperature and humidity conditions. This is crucial for applications with high dimensional accuracy requirements, such as packaging electronic components, ensuring a tight fit and protecting the components from environmental influences.

Special Woven Film Materials

Besides common woven film materials, there are also woven film materials with special properties that play irreplaceable roles in specific fields.

Aluminum-coated woven film is a composite material with special functions. It is typically made by applying a thin aluminum film to the surface of polyethylene or polypropylene woven fabric through processes such as vacuum aluminizing. This aluminum film gives the woven film excellent thermal insulation properties, effectively reflecting solar radiation and reducing heat transfer. In the construction industry, using aluminized Woven Membranes for roofing or wall insulation can significantly reduce indoor temperatures and decrease energy consumption for air conditioning and other refrigeration equipment. In agriculture, as a covering material for greenhouses, it can block excessive heat from entering during summer, creating a suitable growing environment for crops. Aluminized woven membranes also possess excellent waterproof and UV-resistant properties. The aluminum film blocks moisture penetration, protecting the covered materials from dampness and rain; simultaneously, it strongly reflects and absorbs ultraviolet rays, preventing aging and damage and extending the lifespan of items.

Aluminum-plastic woven fabric composite membranes are another important type of special woven membrane material. Composed of a plastic film and an aluminum foil layer, it combines the flexibility of plastic with the barrier properties of aluminum foil. This composite membrane has excellent waterproof and moisture-proof properties, effectively blocking moisture and humidity. In food packaging, it prevents food from becoming damp and spoiling, extending shelf life; in the construction industry, it is used for waterproofing and insulation of roofs and walls, effectively isolating external moisture and protecting the building structure from corrosion. Aluminum-plastic woven fabric composite film also has excellent thermal insulation properties. The aluminum foil layer reflects heat, reducing heat transfer and providing thermal insulation, keeping indoor temperatures warm in winter and reducing energy consumption. Its flexibility makes it more convenient to process and use; it can be cut, folded, and bent according to different needs, adapting to various packaging and construction requirements.

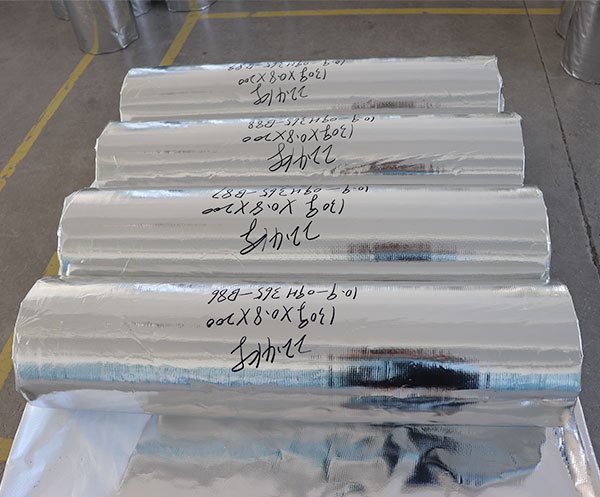

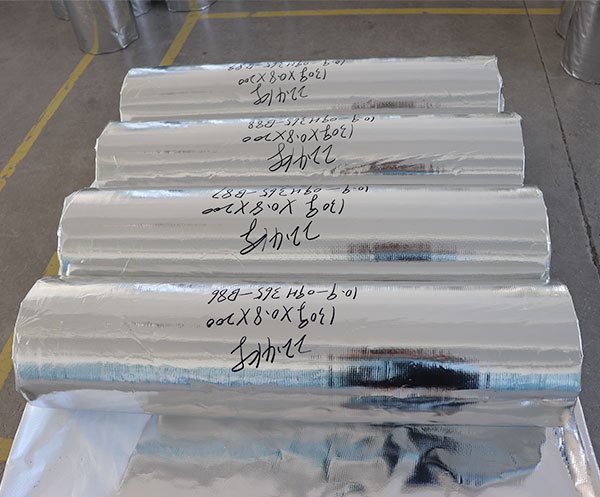

Multifunctional Woven Membrane material: Premium packaging solution for hardware and mechanical parts

The Multifunctional woven membrane material combines protective, adaptable, and practical features, making it an ideal choice for packaging hardware and mechanical parts. It precisely fits bolts, nuts, bearings, gears, and other components, ensuring comprehensive protection during storage and transportation. Its core advantages and application value are as follows:

Comprehensive protective performance ensures part safety. The material is made from high-quality HDPE/PP, produced through precision weaving, and in some variants includes a PE laminated layer. It offers excellent tear and puncture resistance, protecting parts from sharp edges and impacts during handling and transit. Additionally, it provides effective moisture, dust, and chemical resistance, preventing metal parts from corrosion, especially in humid storage environments.

Flexible adaptability meets diverse packaging needs. The material supports full customization of width and length, with thickness adjustable between 0.08–0.25mm. Lightweight options are suitable for individually packaging small precision components, while thicker variants accommodate bulk packaging of heavy mechanical parts. Functional upgrades are also available, including VCI anti-rust additives for corrosion-prone parts, anti-static variants for sensitive electronic mechanical components, and transparent versions for easy visual identification, improving warehouse management efficiency.

Convenient and cost-effective usage. The material can be directly cut and wrapped or processed into packaging bags. Its lightweight nature does not increase shipping costs, and it meets environmental standards. Overall, it provides an efficient and reliable end-to-end packaging solution for hardware and mechanical parts.

Frequently Asked Questions (FAQs):

1. What types of hardware and machinery parts are suitable for packaging with our multi-functional woven film material?

Our multi-functional woven film material is specifically designed for packaging various hardware and machinery parts, including bolts, nuts, bearings, gears, etc. It provides comprehensive protection for these parts, preventing damage from wear, collisions, and environmental factors during transportation.

2. What protective properties does our multi-functional woven film material offer?

This material uses high-quality HDPE/PP as its base material, possessing excellent tear and puncture resistance, effectively resisting punctures from the sharp edges of machinery parts. It also features moisture-proof, dust-proof, and acid and alkali-resistant properties, preventing damage to parts from moisture, dust, and corrosive substances, making it particularly suitable for high-humidity environments.

3. Can I customize multi-functional woven film to meet the needs of different products?

Yes, we offer highly customized services. You can customize the width, length, and thickness of the woven film according to the size, weight, and special requirements of the parts. Common thicknesses range from 0.08mm to 0.25mm, and antistatic or rust-proof functions can also be added to meet different packaging requirements.

4. Is this woven film material suitable for long-term storage?

Yes, woven film material is not only suitable for protection during transportation but also ideal for long-term storage. Its moisture-proof and dust-proof properties effectively isolate moisture and pollutants in the air, ensuring that metal parts do not rust. It is suitable for long-term storage of mechanical parts, hardware accessories, and other items.

5. Does this material require special treatment or pretreatment before use?

No. During use, you only need to ensure that the surface of the parts is clean and dry, and then directly use our woven film for packaging. This material is easy to process; it can be directly cut or made into bags, which is very convenient and saves time.

This website uses cookies to ensure you get the best experience on our website.